Lowidewheels

LWW 2.20 Forged

LWW 2.20 Forged

Couldn't load pickup availability

VEHICLE TAILORED FITMENTS

Custom made-to-order means that we engineer and build every set of forged wheels one-at-a-time from scratch for each individual customer and each unique vehicle application. This consists of not only building the style of wheel and finish color that you want, but also delivering custom sizes and fitments to best match your vehicle and your intended application. Within the limits determined by the wheel style and the forging from which it is made, in most cases, we can create a custom size, lug pattern, and backspace/offset to create the perfect fitment for almost any application!

CUSTOM FINISHING

Every Lowide forged wheel is individually custom finished. This resource-intensive process starts with a painstaking hand-grinding, sanding, & inspection process and concludes with a high-quality hand-applied powder coat that is more consistent & more durable than what would otherwise be possible with a mass-produced alternative. Virtually any color is available, including a large selection of in-stock color options. Three piece wheels can even be finished with different custom color combinations on the center, inner rim, & outer rim!

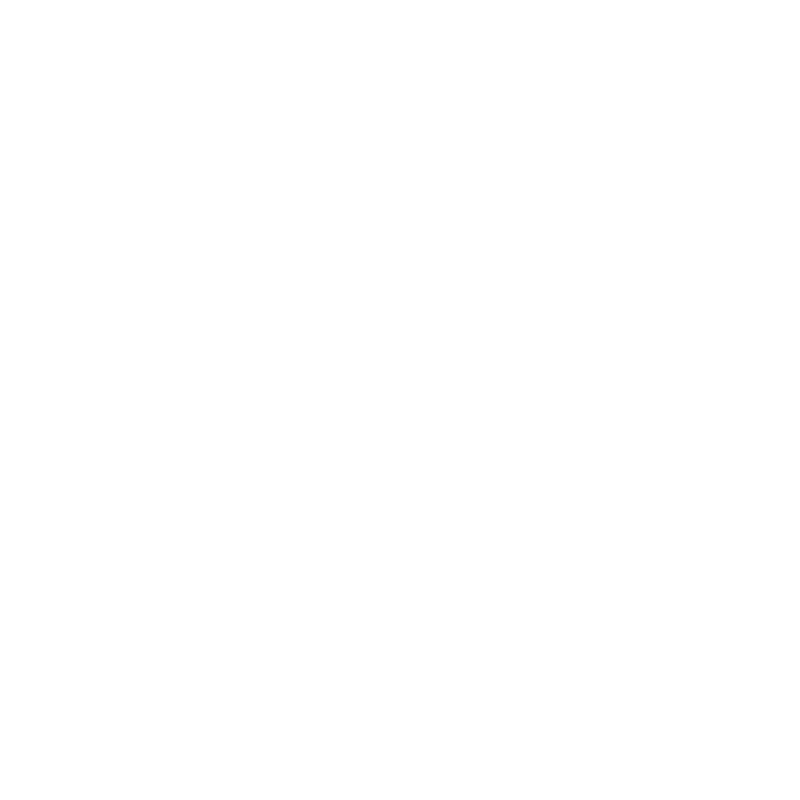

BRUSHED

Brushed finishes are a popular choice in the automotive industry, particularly for forged wheels. This finish is achieved through a meticulous process that involves the use of abrasive materials to create a textured surface. The result is a distinctive appearance that enhances the aesthetic appeal of the wheels while also providing certain functional benefits.

One of the key advantages of a brushed finish is its ability to hide minor scratches and imperfections. The texture created by the brushing process diffuses light, which can make small blemishes less noticeable compared to polished or chrome finishes. This characteristic is particularly beneficial for wheels that are subjected to harsh driving conditions, as they are more likely to encounter road debris and other potential sources of damage.

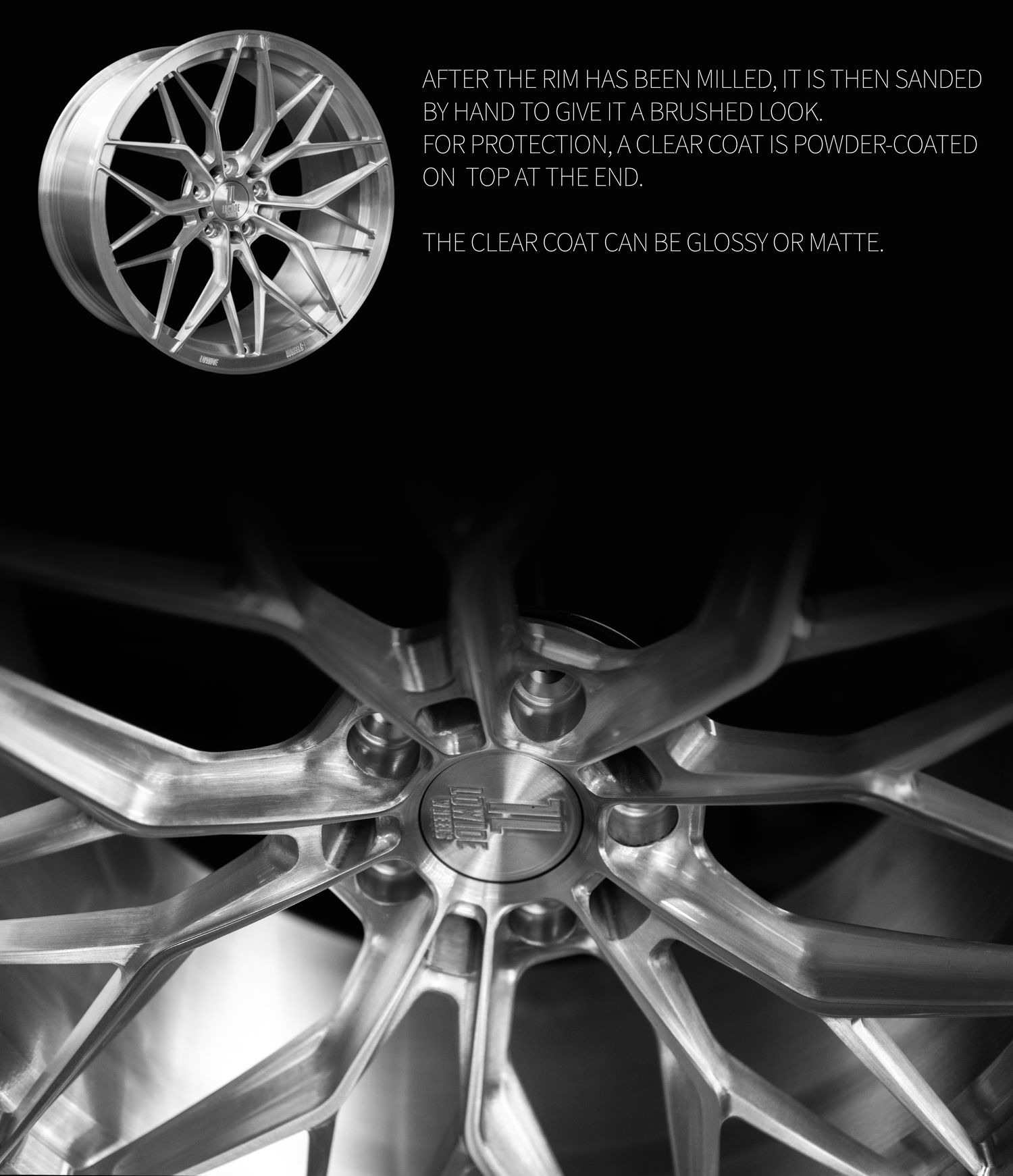

CHROME

Chrome plating is a popular finish for automotive wheels, particularly in the realm of high-performance and luxury vehicles. This process involves applying a thin layer of chromium to the surface of the wheel, which not only enhances its aesthetic appeal but also provides several functional benefits.

One of the primary advantages of chrome plating is its ability to resist corrosion. The chromium layer acts as a barrier against moisture and environmental contaminants, significantly reducing the likelihood of rust formation. Studies indicate that chrome-plated surfaces can exhibit up to 80% better corrosion resistance compared to untreated aluminum or steel surfaces.

However, it is important to note that chrome plating requires specific maintenance to preserve its appearance. Regular cleaning with non-abrasive materials is recommended to prevent the buildup of grime and road salt, which can lead to pitting or dulling of the surface. Additionally, exposure to harsh chemicals or abrasive cleaning agents can compromise the integrity of the chrome finish.

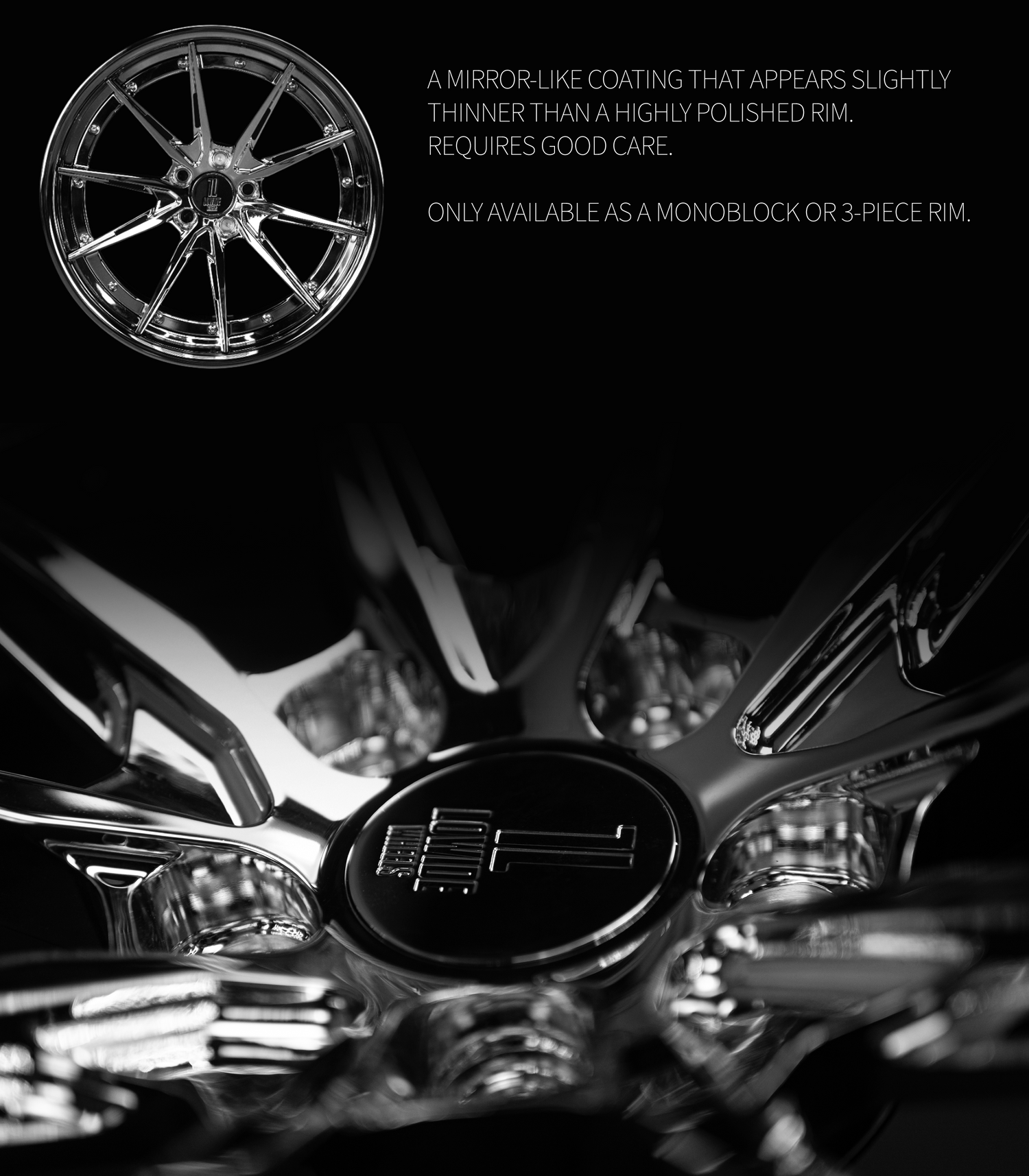

POLISHED

Polished finishes are a popular choice among automotive enthusiasts and professionals alike, particularly in the realm of forged wheels. This finish not only enhances the aesthetic appeal of the wheels but also serves functional purposes that can contribute to the overall performance and longevity of the product.

In the context of forged wheels, a polished finish involves a meticulous process where the surface of the wheel is ground and then polished to achieve a reflective, mirror-like quality. This process can significantly improve the visual impact of the wheel, making it a favored option for those seeking to elevate the appearance of their vehicles.

Statistically, polished finishes are often associated with a higher level of customer satisfaction. Research indicates that approximately 70% of consumers prefer the aesthetic appeal of polished wheels over other finishes, such as matte or painted options. This preference is largely due to the striking visual contrast that polished wheels can create against the body of a vehicle, enhancing its overall design.

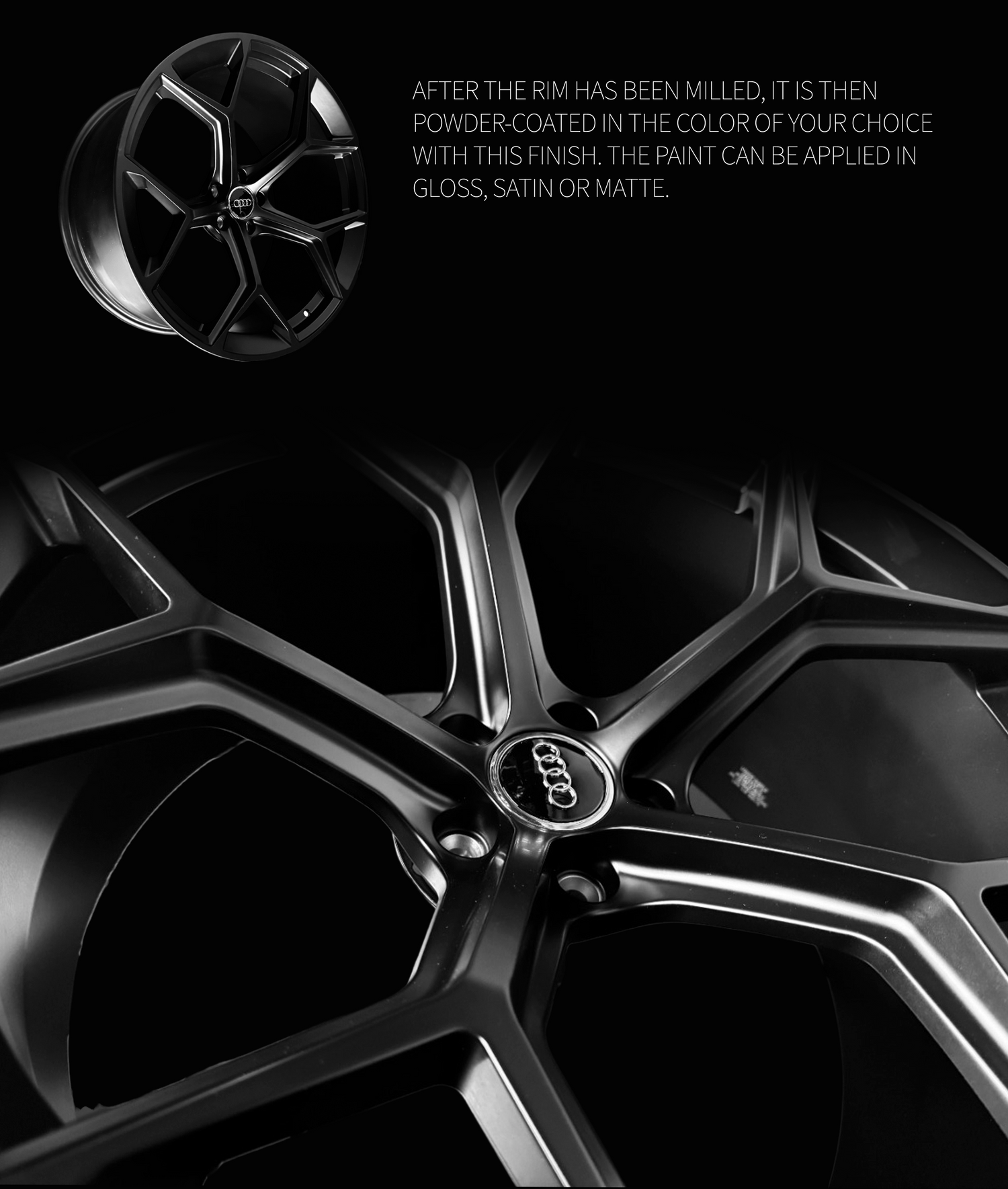

GLOSS / SATIN

This process involves applying a dry powder to a surface, which is then cured under heat to form a hard, protective layer. Among the various finishes available, glossy and satin are two popular options, each offering distinct characteristics and benefits.

Both finishes are available in a variety of colors and can be customized to meet specific design requirements. The choice between glossy and satin ultimately depends on the desired aesthetic, functional needs, and maintenance considerations. It is also important to note that the application process for both finishes remains consistent, ensuring that the durability and protective qualities of the powder coating are maintained regardless of the finish selected.

POLISHED COLOR

The process of achieving a polished color finish typically involves several stages, including machining, polishing, and anodizing. Initially, the wheels are machined from durable materials such as 6061-T6 aluminum, which is known for its strength and lightweight properties. Following machining, the wheels undergo a polishing process that removes any surface imperfections, resulting in a smooth and shiny surface.

Once the polishing is complete, a color anodizing process can be applied. Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant anodic oxide finish. This not only enhances the visual appeal of the wheels but also increases their resistance to wear and tear.

When selecting a polished color finish for forged wheels, it is essential to consider the specific color options available. Common choices include silver, black, and various custom colors that can be tailored to match the vehicle's paint scheme. The choice of color can significantly impact the overall aesthetic of the vehicle, with darker colors often providing a more aggressive look, while lighter colors can enhance the elegance of the design.